EneCap

Why the Aluminum Polymer Capacitors?

SOOSAN ENESOL has developed the Aluminum Polymer capacitors that the solid electrolyte contains an electro-conductive polymer as essential constituent. This product is named the EneCap™. The conductive polymer does not use liquid electrolyte that they will not dry out, leak, or suffer gas buildup and burst. The benefits of EneCap™ on the circuit level over the standard liquid aluminum capacitors are as follows.

Electric storage parts manufacturing technology

| Division | Competitiveness | Competitive advantage cause |

| Uniqueness |

ㆍKorea's only manufacturer of polymer capacitors ㆍMonthly production capacity: : 20Mpcs for 5Φ single product |

ㆍSelf-development of materials, processes, and facilities

-> Highest productivity ㆍRespond to development of various electrode platforms according to products -> Best cost competitiveness |

| Technical |

ㆍDeveloped the world's first 100V high voltage product (2012) ㆍDeveloped the world's only 200V class high voltage product (2017) ㆍDeveloped 150 ℃ Warranty Aluminum Hybrid Capacitor for Automotive Electronics (2021) |

ㆍExcellent product understanding with self-development of key materials, processes and facilities → Unique process ㆍAl electrolytic capacitor, TA capacitor and supercapacitor-related expertise and mixed technology development |

| Quality |

ㆍ125 ℃ / 5,000hrs, 105 ℃ / 50,000hrs warranty ㆍ-55 ~ 150 ℃ temperature guarantee |

ㆍExcellent product understanding with self-development of key materials, processes and facilities → Unique process ㆍVarious electrode platforms → Customized product response technology |

| Product Diversity | ㆍ2.5V to 150V Wide Voltage Range ㆍDiameter 5~10㎜×Height 5~16㎜ Various products |

ㆍSpecialization in polymer polymerization process → Simultaneous implementation of various products ㆍCore equipment self-made → Best compatibility, part commonality |

| Delivery |

ㆍDevelopment sample : 1 week ㆍMass production delivery : 4 weeks / ≥ 1Mpcs |

ㆍSpecializes in high speed, simple and low cost production process → 5 times production speed compared to competitors ㆍCore equipment self-made → Excellent compatibility |

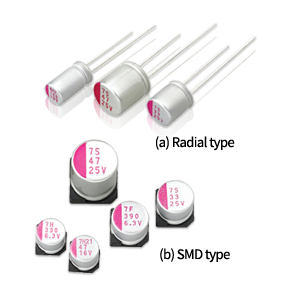

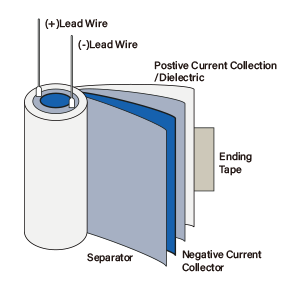

Shape and Structure

Essential passive component For multi-functional and high performance digital devices

Basic performance eliminating of Ripple, wide-band frequency filtering, switching power smoothing

Basic performance eliminating of Ripple, wide-band frequency filtering, switching power smoothing

[ Outside View ]

[ Inside View ]

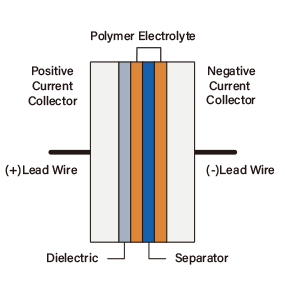

[ Solid Capacitor ]

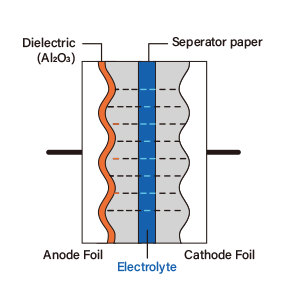

[ Hybrid Capacitor ]

Electric storage parts Manufacturing technology

| Techology | Technical contents | Market status |

| Polymer Capacitor | Conductive polymer applied capacitor manufacturing technology |

ㆍApplied to all industrial fields such as automotive, communication equipment, video equipment, and industry ㆍLeading technology with Japanese companies based on high-voltage, high-reliability technology |

| Hybrid Capacitor | Polymer electrolyte + liquid electrolyte applied capacitor manufacturing technology | ㆍRapid gowth in the automotive market ㆍActive development of Japanese companies ㆍStarted mass production on 2021 |

| Super Capacitor | Winding type capacitor manufacturing technology using electric double layer | ㆍRapid growth in the market with ESS and battery assist ㆍJapaness company leading technology ㆍActive production of domestic NESS and VINATECH |